ABSTRACT

In this study, an energy harvesting chip was developed to scavenge energy from artificial light to charge a wireless sensor node. The chip core is a miniature transformer with a nano-ferrofluid magnetic core. The chip embedded transformer can convert harvested energy from its solar cell to variable voltage output for driving multiple loads. This chip system yields a simple, small, and more importantly, a battery-less power supply solution.

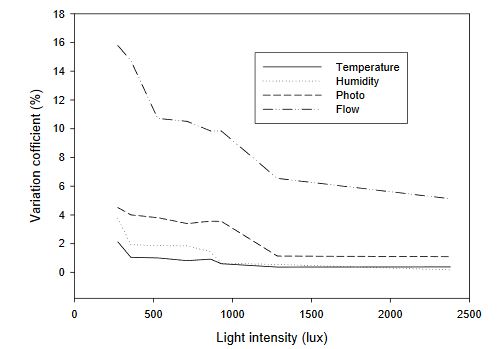

The sensor node is equipped with multiple sensors that can be enabled by the energy harvesting power supply to collect information about the human body comfort degree. Compared with lab instruments, the nodes with temperature, humidity and photosensors driven by harvested energy had variation coefficient measurement precision of less than 6% deviation under low environmental light of 240 lux. The thermal comfort was affected by the air speed.

A flow sensor equipped on the sensor node was used to detect airflow speed. Due to its high power consumption, this sensor node provided 15% less accuracy than the instruments, but it still can meet the requirement of analysis for predicted mean votes (PMV) measurement. The energy harvesting wireless sensor network (WSN) was deployed in a 24-hour convenience store to detect thermal comfort degree from the air conditioning control. During one year operation, the sensor network powered by the energy harvesting chip retained normal functions to collect the PMV index of the store.

According to the one month statistics of communication status, the packet loss rate (PLR) is 2.3%, which is as good as the presented result s of those WSNs powered by battery. Referring to the electric power records, almost 54% energy can be saved by the feedback control of an energy harvesting sensor network. These results illustrate that, scavenging energy not only creates a reliable power source for electronic devices, such as wireless sensor nodes, but can also be an energy source by building an energy efficient program.

ENERGY HARVESTING CHIP

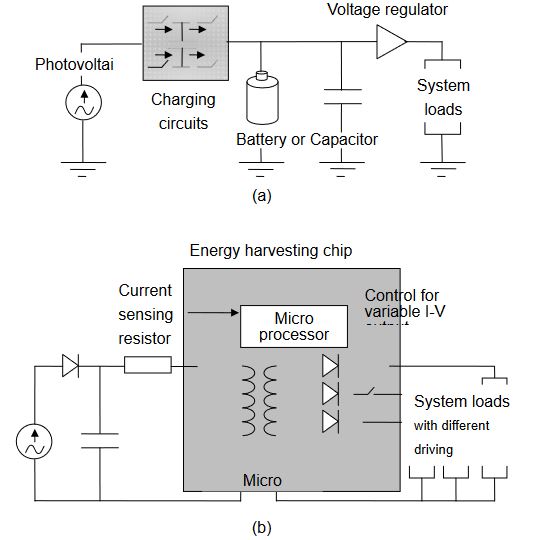

Figure 1. Electrical diagrams of (a) a traditional solar cell charging circuits, and (b) the novel power supply with the energy harvesting chip

The charging circuits must wait until sufficient energy is accumulated in the storage devices before attempting to transfer it to the load. The RC component consists of the load and the capacitor injects low frequency noise to the output, which affect the normal function of a wireless sensor node. Thus, the charging circuits are in turn normally connected with another regulate or for stabilizing power output, as shown in Figure 1a.

EXPERIMENTAL SETUP AND CASE STUDY

In order to verify the effectiveness of the energy harvesting chip and the concepts proposed in this study, the power conversion performances of the chip were tested and compared with traditional charging circuits. The sensor node powered by the energy harvesting power supply sent back data to a central data acquisition system with peer to peer mode and the response times of different sensing elements were measured, with respect to different ambient light intensity.

RESULTS AND DISCUSSIONS

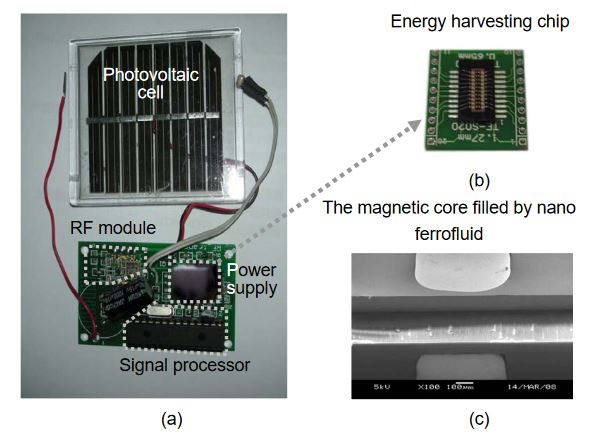

Figure 3 . The pictures of sensor node with the energy harvesting power supply module (a), the energy harvesting chip core

Figure 3 shows the prototype of the energy harvesting power supply, the taped out chip, and the SEM picture of the trench on silicon for the formation of the magnetic core of the transformer. The system on chip provides a simple power solution and minimizes the size of the power supply. As shown in Figure 3a, the occupied area of the power module on the board of the sensor node is even smaller than a microprocessor for sensor signal processing.

Figure 5. The variation coefficient of the measurement precision of the energy harvested sensor nodes with respect to different environmental light intensities

Successful functions of a WSN require precise detection of sensor nodes. In a controlled environment of a laboratory, the sensing accuracies were investigated by comparing the measured results obtained by the energy harvested sensor node and commercial instruments. Figure 5 shows the sensor detection uncertainty, with respect to different environmental light intensities, ranging from 250 to 2,400 lux. The precision of the sensor nodes varied with the amounts of harvested energy.

CONCLUSIONS

The energy harvesting chip was developed to scavenge energy from artificial light to supply power to a wireless sensor node. The chip, embedded with a micro structured transformer, was fabricated by CMOS-MEMS processes. Different from the magnetic film deposition processes, and nano-ferrofluids were employed for the formation of the high-permeability core of the miniature transformer. Capillary force drove the ferrofluids to enter the microchannel to form the flux closure of the primary and secondary coils.

The harvested energy can be stored in the magnetic core and converted to variable voltage output for driving multiple loads. This system, on a chip, yields a simple, small, and more importantly, a battery-less power solution for a wireless sensor node. Using a solar cell, the chip based power supply can provide constant voltage output for the stable works of the signal processor and the sensors equipped on the node. Under the status of no scavenged energy, the energy harvesting chip works to prolong the sensor node’s lifetime.

The driving voltages can be constantly controlled with little offset, and the working status and measured data can be stored in a non-volatile flash memory. The information would not be lost, even when without electric power, and while waiting for the recovery of energy input, the sensor node can resume work sooner. Instead of energy storage, the function of the energy harvesting chip aims to harvest data to retain normal operations of WSN. The energy harvesting WSN was deployed in a 24-hour convenience store.

During one year of operation, the sensor network powered by the energy harvesting chip kept working to collect environmental information and calculate the thermal comfort index PMV for the store. According to one month statistics, the communication quality index, PLR, can be as good as the results of WSNs powered by battery. The “deploy and forget” scenario was demonstrated. No more concerns over regular maintenance and battery replacement. A renewable and sustainable power source was exploited.

Source: National Taipei University

Author: Dasheng Lee

>> More Wireless Embedded Projects for Final Year Students

>> More Wireless Energy Projects for Final Year Students