ABSTRACT

Li-Ion batteries are widely preferred in electric vehicles. The charge status of batteries is a critical evaluation issue, and many researchers are studying in this area. State of charge gives information about how much longer the battery can be used and when the charging process will be cut off. Incorrect predictions may cause overcharging or over-discharging of the battery.

In this study, a low-cost embedded system is used to determine the state of charge of an electric car. A Li-Ion battery cell is trained using a feed-forward neural network via Matlab/Neural Network Toolbox. The trained cell is adapted to the whole battery pack of the electric car and embedded via Matlab/Simulink to a low-cost micro controller that proposed a system in real-time. The experimental results indicated that accurate robust estimation results could be obtained by the proposed system.

MATERIALS AND METHODS

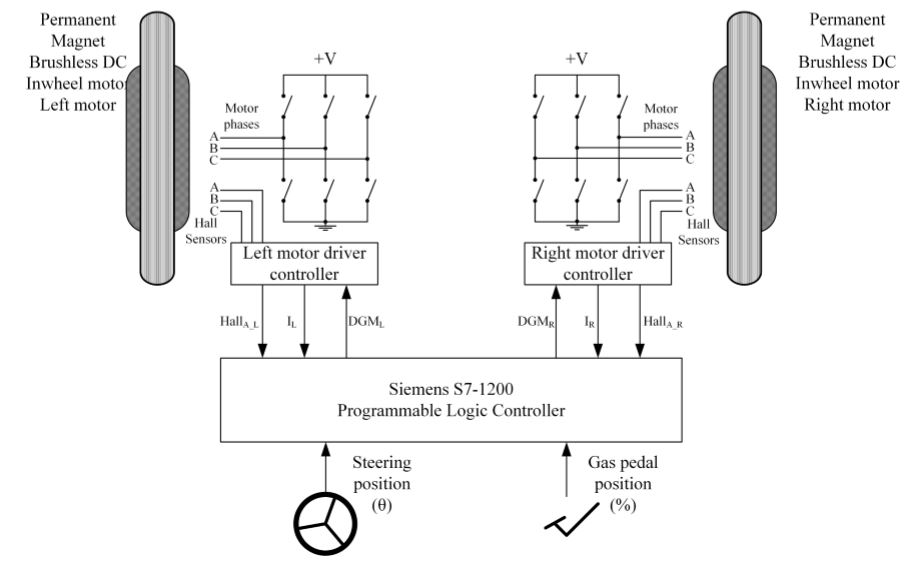

An electric car is developed to compete in the TUBITAK Efficiency Challenge Electric Vehicle event. The schematic layout of the electric car is given in Figure 1.

Figure 1. Schematic layout of the electric car

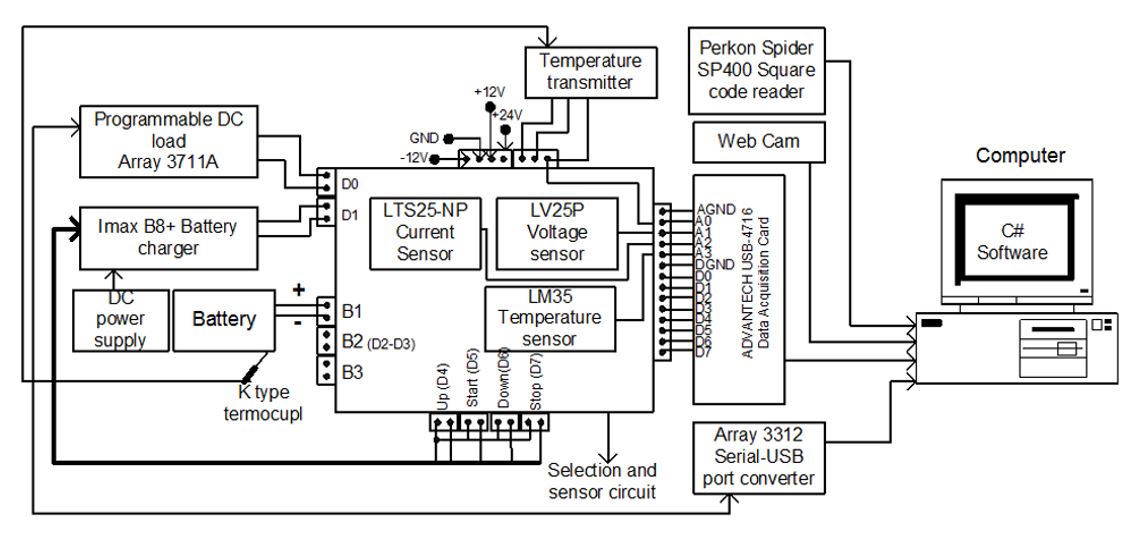

In this study, an experimental setup is developed to collect electrical measurement data while charging and discharging the battery cell. Open circuit voltage, current, power, load, ambient temperature and battery temperature are measurement parameters. The measurement setup of this study is given in Figure 2.

Figure 2. Measurement setup

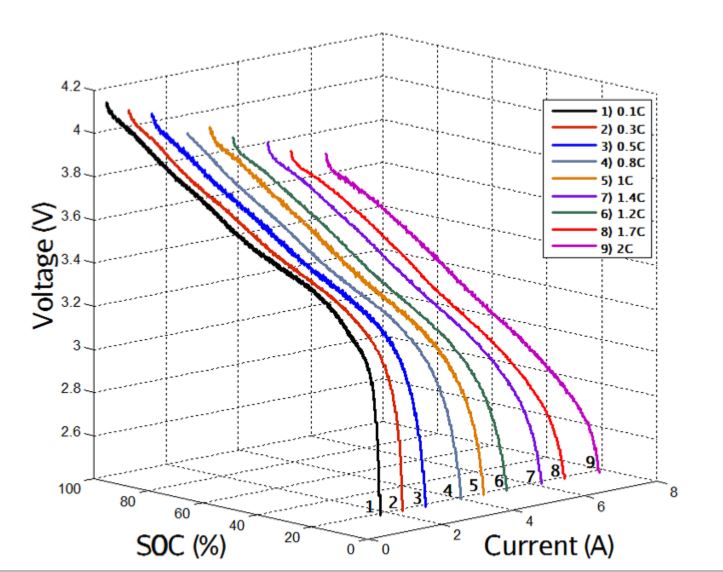

To obtain the data set for usage to determine the SOC of the battery pack, the battery cell is fully charged firstly and then fully discharged at constant current levels. In Figure3, from left to right, 0.1C, 0.3 C, 0.5 C, 0.8 C, 1 C, 1.2 C, 1.5 C, 1.7 C, and 2 C constant current discharging curves are given. This experimental data is used as training data for FFNN to determine the SOC of the battery. The electric car that we used in experiments does not support regenerative breaking; for this reason, only discharge data is used to train the neural network. However, it is possible for a mixture charge–discharge data pool to develop an ANN.

Figure 3. Discharging curves at different constant current levels

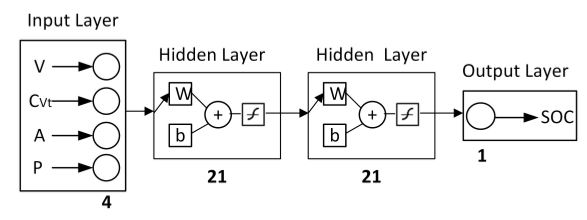

The counter increments if the voltage is the same as the previous voltage measurement value and resets if these two parameters are different. Using only current or only voltage value gives incorrect estimation results. Using P and CVt values increases the performance of the neural network. The input values of FFNN are normalized between 0 and 1 by dividing input value into the absolute maximum input vector value. The architecture of FFNN to determine the SOC of the battery is given in Figure 4.

Figure 4. Feed forward neural network architecture of the study

RESULTS AND DISCUSSION

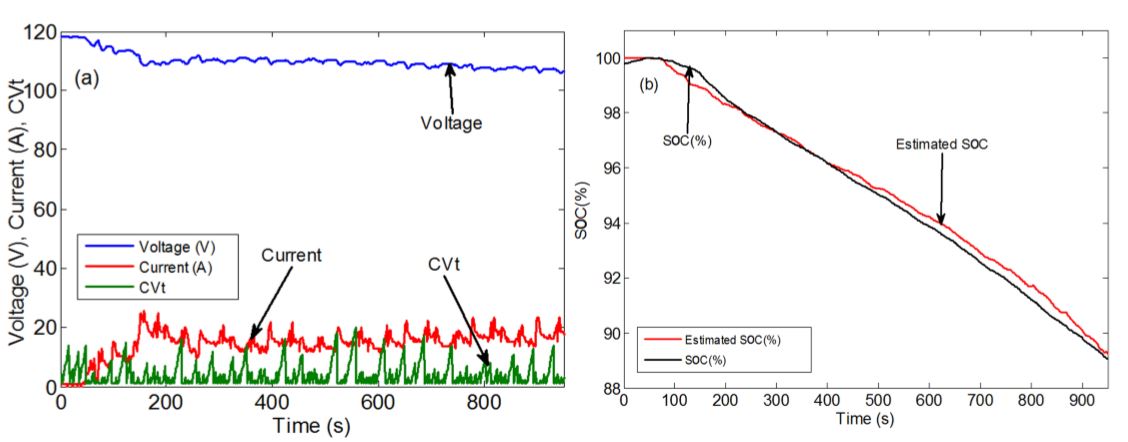

The system is tested on the electric car at the TUB ITAK efficiency Challenge Electric Vehicle in 2016 in Kocaeli/Turkey. A photo of the electric vehicle is given in Figure 8. Three drives have been done on the driving track. Real-time measurements and battery packs SOC estimations corresponding to these measurements are given below. Figures 9–11 first present graphs of battery voltage, current and CVt parameters, and, in the following graphs, SOC and estimated SOC of the battery are given. The estimated SOC of the relative battery error rates of the first experiment is 0.75%, the second experiment is 0.27%, and the third experiment is 0.14% respectively. The average success rate is 99.61%. The results show that the system operates successfully.

Figure 8. Driving test of the electric vehicle

Figure 11. (a) Battery voltage, current and CVt parameters; (b) SOC and estimated SOC of the battery

CONCLUSIONS

In this study, an Li-Ion battery cell is trained using FFNN. The trained cell is adapted to an entire battery pack and used for estimating the SOC of an electric car in real time. The data set to train FFNN is obtained from discharge curves of a single battery cell at different C rates at constant currents. The model developed in Matlab/Simulink is embedded in the low-cost STM32F4DISCOVERY kit. The system is tested in real time on the electric car and performs with a 99.61% success rate.

Modelling a single cell and adapting the model to a whole battery pack made the experiments easier and time and cost savings were achieved. The CVt parameter is an innovation of this study. Using CVt parameters as an input variable of FFNN reduced the incorrect estimations and increased the system’s accuracy. In closing, this study performs well in real-time SOC estimation of an electric car. It is possible to adapt the system to systems that include battery packs. Furthermore, this study can be used in range prediction of electric vehicles.

Source: Karabuk University

Authors: Emel Soylu | Tuncay Soylu | Raif Bayir

>> 200+ Matlab Projects based on Control System for Final Year Students

>> For More Matlab Projects on Embedded Systems for Final Year Students