ABSTRACT

A planogram is a detailed visual map that establishes the position of the products in a retail store. It is designed to supply the best location of a product for suppliers to support an innovative merchandising approach, to increase sales and profits and to better manage the shelves. Deviating from the planogram defeats the purpose of any of these goals, and maintaining the integrity of the planogram becomes a fundamental aspect in retail operations.

We propose an embedded system, mainly based on a smart camera, able to detect and to investigate the most important parameters in a retail store by identifying the differences with respect to an “approved” planogram. We propose a new solution that allows concentrating all the surveys and the useful measures on a limited number of devices in communication among them.

These devices are simple, low cost and ready for immediate installation, providing an affordable and scalable solution to the problem of planogram maintenance. Moreover, over an Internet of Things (IoT) cloud-based architecture, the system supplies many additional data that are not concerning the planogram, e.g., out-of-shelf events, promptly notified through SMS and/or mail.

The application of this project allows the realization of highly integrated systems, which are economical, complete and easy to use for a large number of users. Experimental results have proven that the system can efficiently calculate the deviation from a normal situation by comparing the base planogram image with the images grabbed.

SMART CAMERA DESCRIPTION

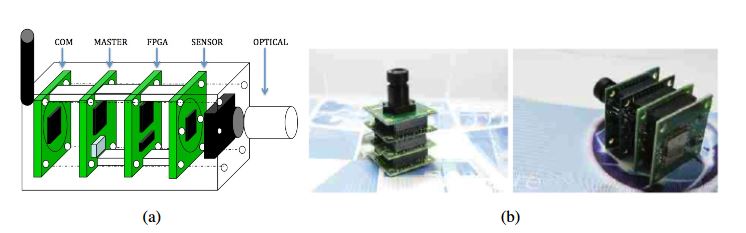

Figure 1. (a) Illustrative scheme; (b) Two views of the real camera. The smart camera

Since not all measures, such as humidity, may be detected by the camera, to make the smart camera an open device adaptable to future needs, we included a serial-type external communication interface with the inter-integrated circuit (IIC) standard to link external devices. Figure 1 shows an illustrative scheme (Figure 1a), which highlights the five different components, and two different views (Figure 1b) of the smart camera.

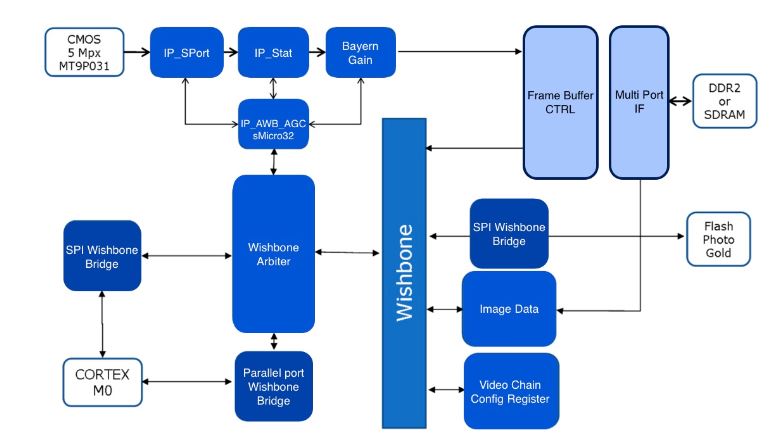

Figure 4. Flowchart of the FPGA operations Figure 4. Flowchart of the FPGA operations

To take advantage of this speed, the image acquisition module must be connected directly on the board with the operating system iMX6 or directly to the network via a 1-Gbit Ethernet port. In this work, we take into account the first case by developing a specific driver for the operating system. Figure 4 describes the sequence of operations of the FPGA. In the following, the single functions are briefly listed:

• IP sport: interface towards the sensor;

• IP core stat: statistics of the image in real time;

• IP Bayer gain: management of gains for each channel;

SMART CAMERA: AN IMAGE PROCESSING APPROACH TO PLANOGRAM INTEGRITY

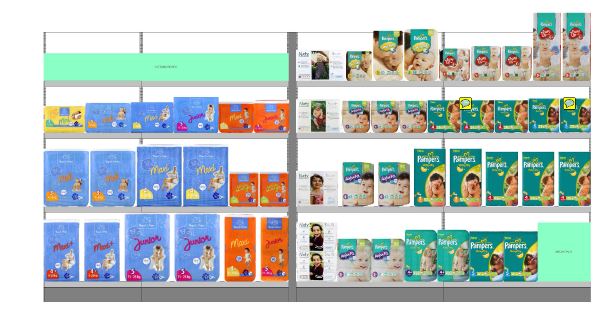

Figure 5. Example of a planogram used in the retail market and described by an XML file

Figure 5 shows an example of a frontal image of product positioning. The smart camera described in the previous section provides images to capture the physical location of products on the shelves. The smart camera system knows the planogram, i.e., the better position of the products on the shelves. Therefore, to detect planogram integrity, the system automatically matches the approved planogram, stocked on the server, and the pictures from stores.

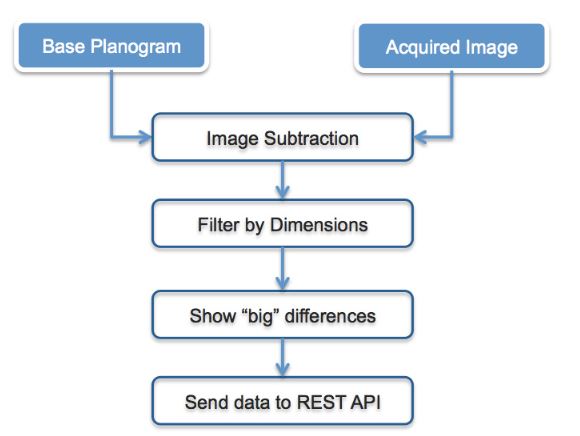

Figure 6. Representation of the implemented image processing algorithm

Analyzing Figure 6, the algorithm processes two input images: the image representing the accepted planogram (base planogram) and the image acquired by the smart camera at a later time. It has to establish how the actual image is different from the planogram accepted as correct. Image subtraction is the result of this comparison.

SENSOR CLOUD ARCHITECTURE

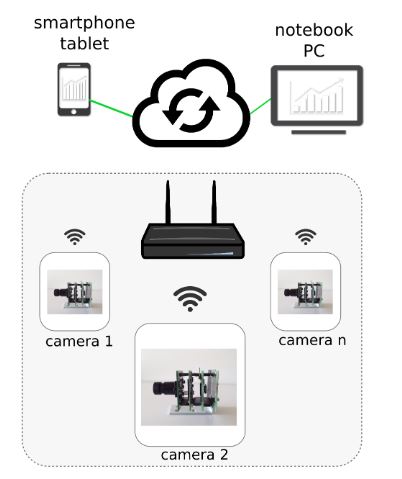

Figure 8. The sensor cloud architecture

Figure 8 shows a representation of the sensor-cloud infrastructure. Basically, every camera is a sensor node that transmits synthetic raw textual data to the cloud over the Wi-Fi connection. Therefore, each camera communicates with the cloud architecture by means of Wi-Fi transmission data. Data can be processed through different devices (smartphone, tablet or notebook).

RESULTS

Figure 9. Representation of the experimental setup

In the experimental phase, the camera was fixed at two meters above the floor at a distance of 3.5 m with respect to the center of the shelf. The maximum visualization area was 1.8 m × 3.2 m, wider than the height of the shelf (1.5 m). This experimental setup is shown in Figure 9. The camera is in a fixed central position, and in this experimental phase, we have not tested the performances of the system by rotating or translating the camera.

CONCLUSIONS

In a retail store, the use of a planogram is important for different aspects: increasing sales, increasing profits, introducing a new item, supporting a new merchandising approach and better managing the shelves. The planogram is often used in retail operations as a means of visual merchandising. A problem related to the planogram is maintaining its integrity: real-time integrity is a crucial problem for vendors.

The respect of the position of products on an accepted planogram implies attracting and motivating a costumer to purchase a product. The research described in this paper proposes a new embedded system that is highly integrated, economic, complete and easy to use for a large number of users. To evaluate the integrity of the planogram, a smart camera estimates the difference image between the base planogram and reference images.

We also reported preliminary results as regards the planogram integrity. The results are efficient, since the system in real time provides information concerning both the deviation from the planogram and out-of-shelf events. The actual solution proposed in this paper is a really smart solution, battery-based (not common for visual sensors) and able to automatically perform planogram maintenance measurements with precise feedback from users. The solution is also low cost and provides an industrial solution with high scalability for retailers.

The data solution, cloud based, but with distributed processing, is also very inexpensive and simple. There are no particular limitations, and the solution, developed together with a company working in retail technologies, seems to be a nice Columbus’s egg. The main improvements can be done in the design of a plastic box and on the strong optimization of power consumption, to be able to have a two-year battery life, maintaining low cost and small dimension constraints.

Source: University Politecnica delle Marche

Authors: Emanuele Frontoni | Adriano Mancini | Primo Zingaretti

>> 200+ IoT Led Engineering Projects